- 36 sets of heddle belt + heddle wire, 18 of heddle wires stations in each group, total 648 pcs.

- Rolling reed structure is beneficial to the oil-free fabric, enhancing the film coating effect and meets the requirements of food-grade products.

- The main motor is 3KW Siemens variable frequency drive.

- With automatic refueling cup, you can set the refueling time and refueling amount on the control screen.

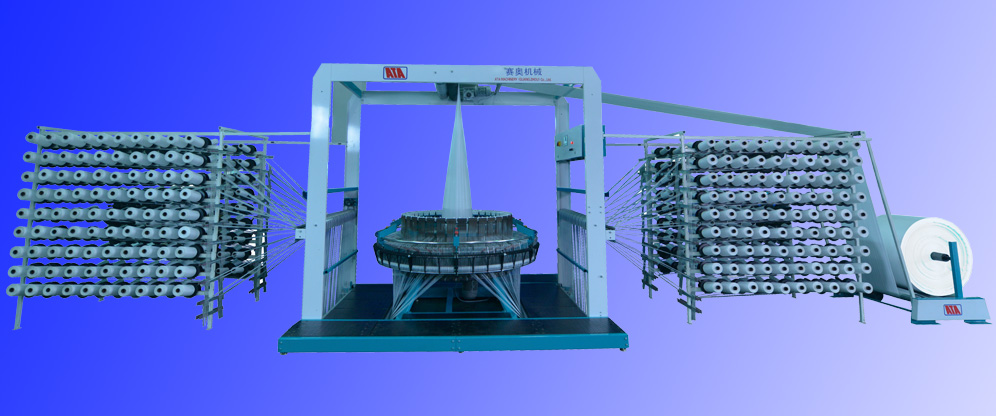

Circular Loom Asiastar-6L

Model Asiastar-6L

Fold width 450-850mm

Shuttle number 6梭

Weft insertion (max.) 150rpm

Fold width 450-850mm

Shuttle number 6梭

Weft insertion (max.) 150rpm

Applications

The circular loom aims at achieving high-efficiency and high-tech weaving, and meets the uninterrupted weaving of PP or HDPE yarns. It is suitable for the production of standard bag cloth such as chemical bags, cement bags, and feed bags.

The main machine consist

Main machine

Shuttle

- The shuttle is equipped with a weft yarn tension automatic control device.

- The shuttle is equipped with front and back Block yarn plate, which can load max 110mm dia weft yarn.

Weft break / weft end

- Weft break detection system

- 1 set of magnetic sensor monitors the weft yarn. Ensure that the machine stops automatically when the weft breaks. Weft end detection system

- Equipped with a photoelectric sensor to control the automatic shutdown when the weft is used up.

- It is recommended to use black bobbins for best results.

Warp Tension Balance System

- There is a let-off roller on each side of the main machine

- Each let-off roller is equipped with a let-off motor: power: 0.09kw

- There is an aluminum godet roller under each let-off roller, and the godet roller is equipped with a load cell.

- Ensure that the warp yarn is smoothly fed into the host and maintain real-time tension balance.

Circular loom control system

- Self-developed PLC controller;

- Five inverter control;

- The control panel can be set: Adjust the weft density; set the length of the cloth roll; order instructions.

- Four-shift output display; running time display; roll change/cloth roll indicator

- Equipment evaluation system: The running time of the equipment; the number of warp yarn breaks; the number of weft yarn breaks; the number of weft ends, etc.

Fabric winding device

- A friction type of winding device is equipped with a load cell, which is controlled by a 0.37KW inverter, and the winding motor is a 1.8NM torque motor.

- We offer a 3″ roll core (standard size). Remarks: 4".6" roll core can be selected - Need to be customized

Technical Parameter

| Shuttle/ machine | 6pcs |

| Working width | 450-850mm |

| Weft insertion (max.) | 1000ppm |

| Weft density | 20-75pcs/10cm |

| No. of warp tapes * | 648pcs |

| Warp/weft core inside diameter | 35mm |

| Warp/weft core length diameter | 220mm |

| Warp bobbin diameter(max.) | 160mm |

| Weft bobbin diameter(max.) | 110mm |

| Winding roll diameter(max.) | 1200mm |

| Max. weight | 1600kg |

| Overall size | 9500x2750x2850mm |

HOME

HOME