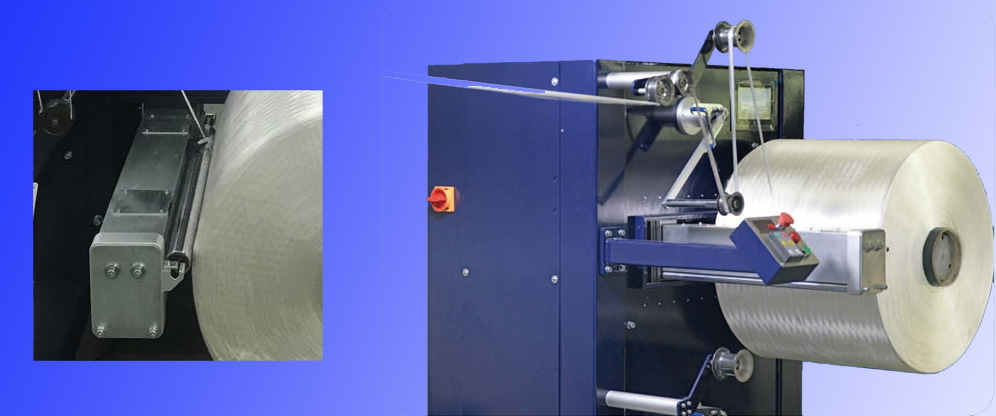

AW60 Winder

Winding Ratio: electronic

Tube ID: 144mm

Doffing structure: pneumatic yarn pushing device

Tube ID: 144mm

Doffing structure: pneumatic yarn pushing device

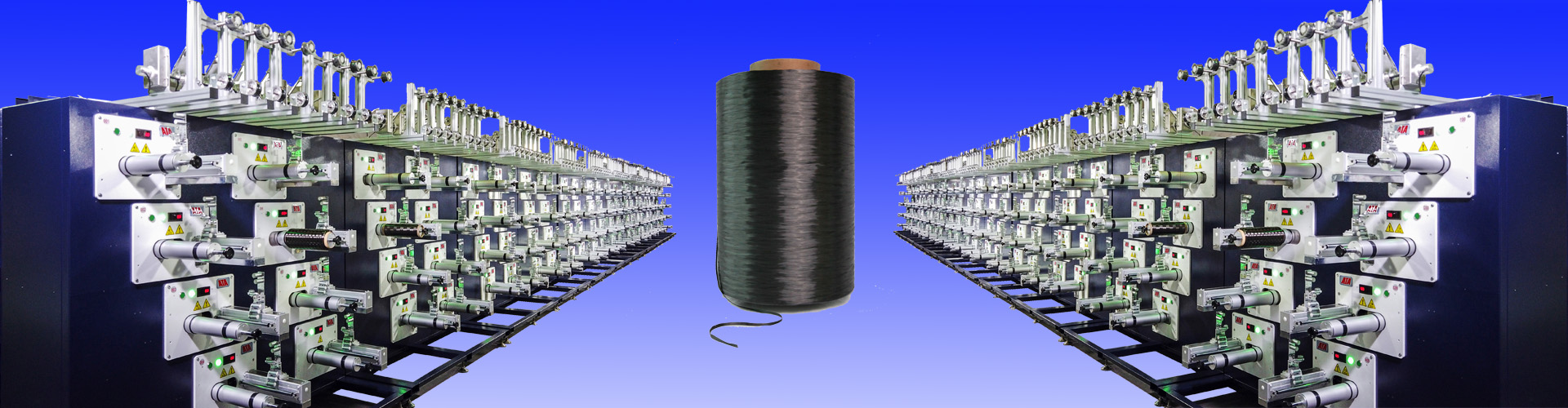

Product application

This model suitable for: the rewinding of carbon fiber precursor.

The winder is designed for carbon fiber precursor, the structure of electronic control and machinery are totally designed for the rewinding of super big spindle which can fully meet with the rewinding of carbon fiber precursor. The contact pressure can be set and adjustable together to ensure the perfect shape of big spindle and consistent tension of yarn inside and outside. The operation is simple and visual.

Technical characteristics

- Electronic winding ratio: precise electronic winding ratio, it can achieve precise winding through randomly changing winding parameters and patterns according to the specification of fiber.

- Variable winding ratio: it can be set randomly which is benefit to the winding of big spindle with the perfect shape and without the fallen yarn.

- Electronic tension control: it can be adjusted online through the uniform setting on man-machine interface. The tension is balanced and consistent with high precision.

- Doffing structure: pneumatic shaft locks the bobbin tightly and pneumatic yarn pushing device, reserve a place for mechanical arm core shaft, avoid damaging the quality of fiber.

- Contact pressure control: special design of contact pressure method, can be set uniformly through the man-machine interface. The contact pressure will reduce gradually with the winding diameter enlarges.

- Traverse control: adopting servo drive, high precision of yarn guide and perfect shape.

- Yarn guide roller: all yarn guide roller adopt ceramic surface treatment which have no damage for yarn with high durability.

- Length/Winding diameter setting: winding length and winding diameter can be set with early pre-warning function and full change-over warning prompt function.

- Processing parameter storage: all processing parameter can be stored in PLC and used directly after confirmation. It can store max 10 kinds of processing parameters.

- Special yarn feeding way, to ensure consistent yarn width.

- The design structure of whole machine is compact with less easy damaged spare parts and convenient maintenance.

Technical specification

| Model | AW60L | AW60H |

| Winding Ratio | Electronic | Electronic |

| Titer | 1-24K | 12-48K |

| Winding Speed | 70-250m/min | 50-150m/min |

| Max Spindle Weight | 120kg | 300kg |

| Tube ID | 144mm* | 144mm* |

| Tube Length | 550mm* | 750mm* |

| Traverse Length | 500mm* | 700mm* |

| Frame Structure | 2 tiers, single row | 1 tier, single row |

HOME

HOME